Directional drilling technology has transformed the way underground resources are accessed and construction is developed. This innovative technique permits drillers to construct wells that deviate from a straight path, enabling targeted access to petroleum and natural gas deposits, the placement of infrastructure systems, and the development of pipelines even in adverse environments. For those unfamiliar to the field, understanding what directional drilling involves and the positive aspects it provides can seem daunting. This guide aims to clarify directional drilling, investigating its various uses, advantages, and the advancements that are driving its evolution.

As the demand for efficient and sustainable construction methods grows, directional drilling becomes crucial as a key innovation. From its early adopters in the oil and gas industry to its expanding role in sustainable energy and metropolitan infrastructure, this technique showcases the industry’s potential to adjust and grow. In this write-up, we will delve into the complexities of directional drilling, contrasting it with conventional techniques and examining the tools and technologies that make it possible. Whether you're a curious beginner or an industry professional seeking information, you'll find valuable information on the practices, challenges, and promising future of directional drilling.

Comprehending Directional Borehole Drilling

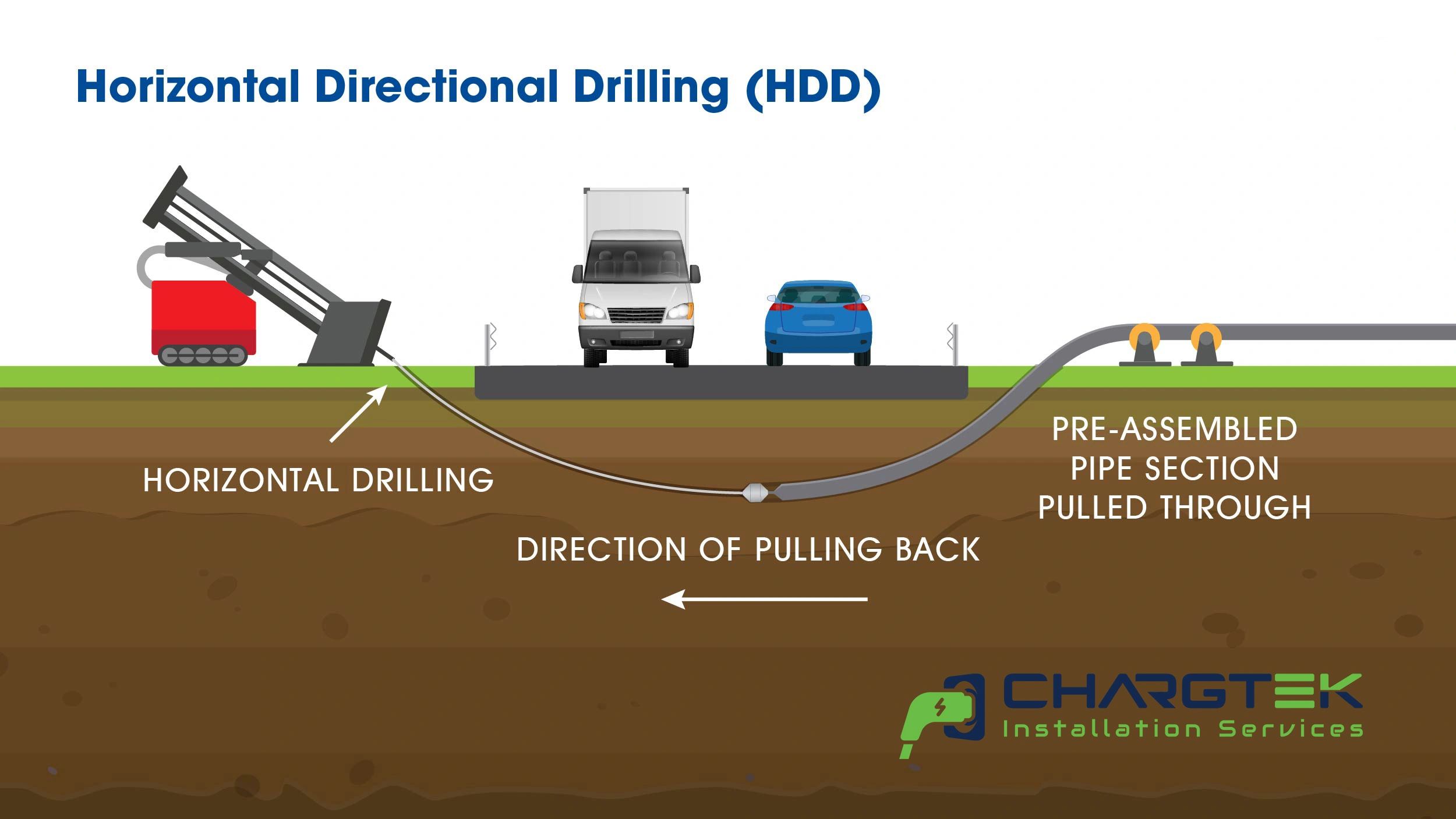

Directional drilling is a method that facilitates the drilling of holes at various angles rather than only upright, which allows for more effective resource extraction. This method is frequently employed in the oil and gas industry but has also established applications in infrastructure projects, building, and sustainable energy initiatives. By enabling the boring of sideways or angled wells, this method optimizes the placement of drill sites, making it viable to tap into reservoirs that would be out of reach using conventional vertical drilling methods.

One of the main advantages of this technique is its potential to reduce environmental disruption. Conventional boring frequently necessitates extensive land disturbance and can affect the local ecosystem significantly. In opposition, this method allows operators to drill from a unified location to tap into several targets below ground. This means fewer drill sites, minimized interference to the surroundings, and minimized influence on communities and ecosystems. The technique has become vital in fragile locations, where ecological preservation and land integrity are paramount.

To successfully carry out this technique, several advanced tools and gear are employed. For example, well tracking systems, mud motors, and tailored boring tools help secure accuracy and efficiency throughout the drilling operation. The mapping of the drill path is essential, as it requires a comprehensive grasp of geological formations and the intended targets. As innovation progresses, the approaches and machinery used in this field are constantly advancing, presenting opportunities for greater precision, effectiveness, and minimal influence.

Benefits and Advantages

Directional drilling offers numerous benefits which enhance efficiency and effectiveness in different industries. A primary of the key advantages is its capability to reduce surface disruption. By drilling at angles or on a horizontal plane, this technique allows for the installation of pipelines and utilities without the need for significant excavation. This feature is particularly valuable in urban areas where road closures and surface disturbances can lead to significant inconvenience and economic loss.

Moreover, directional drilling can cut both time and money compared to traditional drilling methods. The accurate positioning of boreholes reduces the need for multiple drilling sites and mitigates the logistics challenges associated with large-scale excavation. Vacuum Excavation Northern Ireland project schedules but also decreases labor and material costs, making it a financially attractive choice for companies in sectors such as oil and gas, utility installation, and renewable energy.

Lastly, the environmental advantages of directional drilling cannot be overlooked. By minimizing the area affected during drilling operations, this method minimizes the ecological impact and helps protect surrounding landscapes. In addition, it is particularly suitable for sensitive locations, allowing for infrastructure development without compromising environmental integrity. As industries increasingly focus on eco-friendly practices, directional drilling stands out as a solution that aligns with both operational goals and environmental stewardship. spintax ### Future Advancements in Horizontal Drilling

As the need for more effective and environmentally friendly construction practices grows, the future of directional drilling is predicted to be influenced by innovations in technological and automation. Innovative developments such as immediate data analytics and advanced modeling software are enabling operators to more effectively predict drilling routes and improve processes. This greater accuracy in planning and execution merely improves the efficiency of projects while also reduces financial outlays and resource consumption.

Artificial Intelligence is additionally playing a crucial role in the evolution of directional drilling practices. AI-driven systems can analyze extensive amounts of data from former drilling projects to spot patterns and suggest the best strategies for next endeavors. Machine learning algorithms improve decision-making processes, thus enhancing safety and performance on-site. As these technologies become more embedded into drilling operations, we can expect notable improvements in overall project delivery times and a decrease in the chance of costly mistakes.

Eco-friendliness is expected to be a major driving force behind the future of directional drilling. As urban settings expand and infrastructure demands rise, the ability to minimize surface disturbance becomes increasingly essential. New developments in green drilling fluids and equipment designed to operate with a reduced environmental footprint will support this transition. This focus on sustainable practices in directional drilling not only matches with global environmental goals but also prepares the industry to meet the challenges of future urban and energy needs effectively.